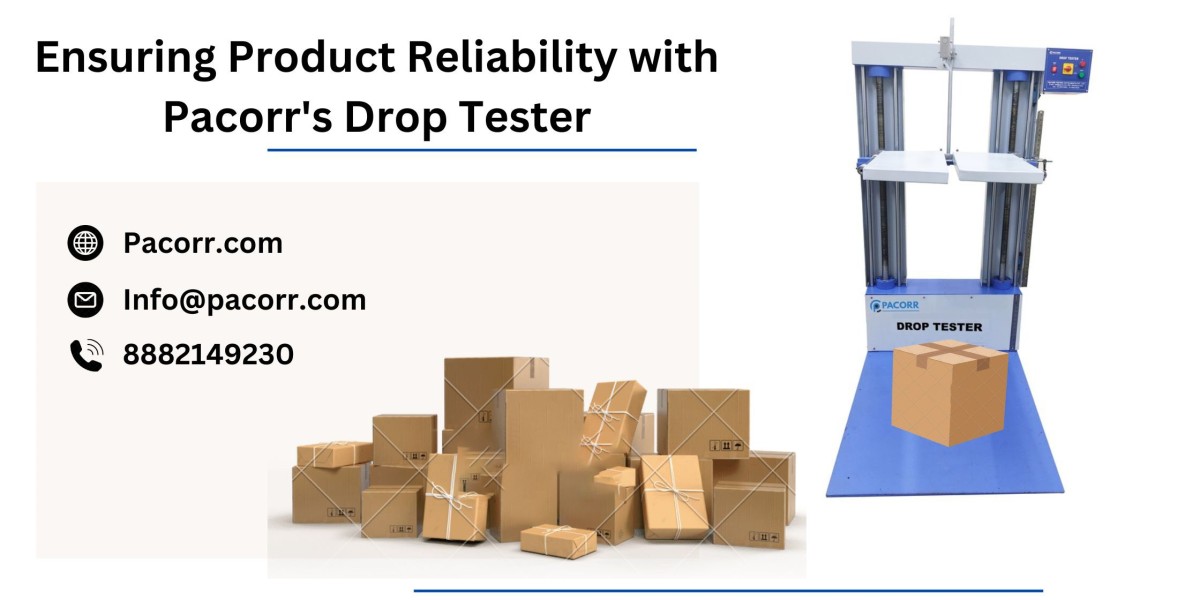

What is a Drop Tester?

The Drop Testing is a specialized device that evaluates the strength and durability of packaging materials. By simulating the conditions of a free fall, this equipment allows manufacturers to assess how well their packaging can withstand sudden impacts. Packages are dropped from specific heights to simulate real-world conditions, helping to ensure that the packaging can adequately protect its contents during transport and handling.

Notable Features of the Drop Tester

- Variable Drop Heights: The Drop Tester can be adjusted to various heights, allowing for the simulation of different scenarios and the assessment of packaging performance under a range of conditions.

- Accurate Testing: Engineered for precision, the Drop Tester provides consistent and reliable results, giving manufacturers confidence in the data it produces.

- Durable Design: Constructed from high-quality materials, the Drop Tester is built to withstand rigorous testing, ensuring long-term reliability.

- Versatile Applications: This testing equipment can accommodate a variety of packaging types, from boxes and cartons to containers of different sizes and weights.

- Easy-to-Use Interface: The Drop Tester Price is equipped with a user-friendly control panel, allowing operators to easily set test parameters and conduct tests efficiently.

The Importance of Drop Testing

Drop testing is a crucial part of packaging quality control. It helps ensure that packaging is strong enough to protect the product from damage during its journey from the warehouse to the customer. If packaging fails during transit, it can lead to damaged goods, dissatisfied customers, and potential harm to a brand’s reputation.

The benefits of using a Drop Impact Tester include:

- Minimizing Product Damage: By identifying weak points in packaging before it is used, manufacturers can prevent product damage during transportation.

- Ensuring Compliance: Many industries have specific standards for packaging. Drop testing helps ensure that packaging meets these requirements, avoiding potential legal and financial issues.

- Boosting Customer Satisfaction: Ensuring that products arrive in perfect condition is key to maintaining customer trust and satisfaction. Proper packaging testing helps achieve this goal.

Industries that Benefit from Drop Testing

The Drop Tester is valuable across a wide range of industries, including:

- Electronics: Protecting delicate electronic devices during shipping.

- Pharmaceuticals: Ensuring the integrity of packaging for sensitive medical products.

- Food and Beverage: Testing packaging durability to prevent spoilage and contamination during transit.

- E-commerce: Evaluating the packaging of goods sold online, where multiple handling points are common.

Conclusion

Pacorr’s Drop Tester is an essential tool for businesses that prioritize the safety and durability of their products. By simulating the conditions packages face during transport, this equipment helps ensure that products reach customers in the best possible condition. Investing in drop testing not only enhances product safety but also helps build a strong reputation for quality and reliability.

For more details on the Drop Tester and other testing solutions, visit Pacorr Testing Instruments Pvt Ltd.