Establishing an isophthalic acid manufacturing plant requires a thorough understanding of the chemical’s production process, its market demand, and the associated financial and regulatory challenges. A well-structured Isophthalic Acid Manufacturing Plant Project Report provides all the necessary details for planning, building, and operating such a facility. This article highlights the key components of a project report, the factors influencing production, and the benefits of leveraging advanced procurement resources.

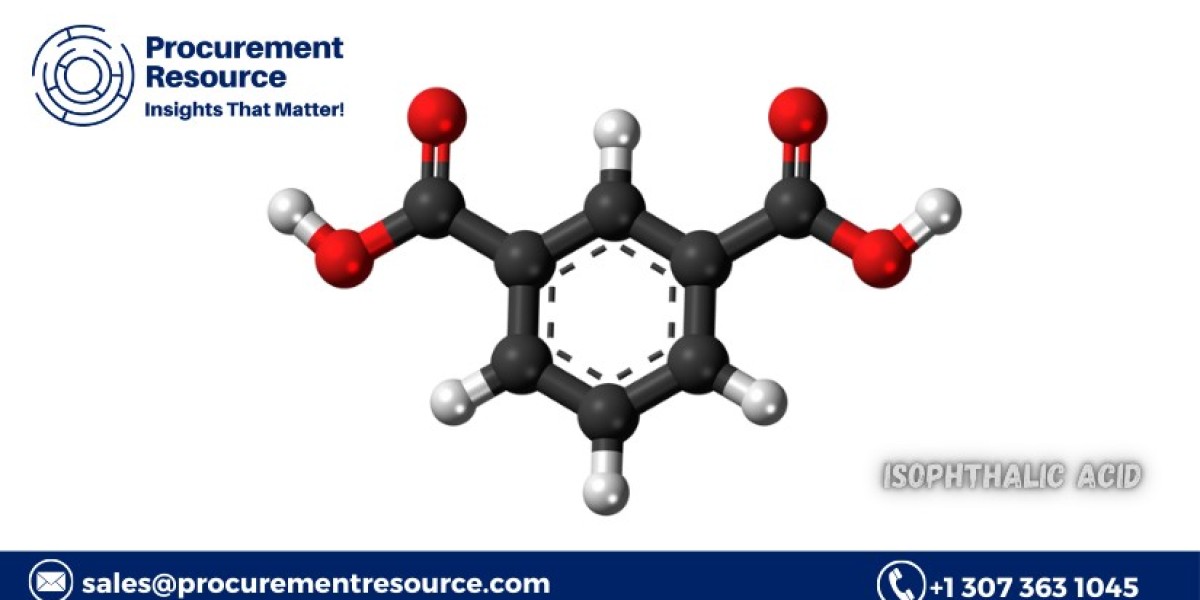

Isophthalic Acid: Characteristics and Applications

Isophthalic acid is an aromatic dicarboxylic acid widely used in various industries due to its excellent thermal stability, chemical resistance, and ability to enhance polymer properties. Produced through the oxidation of meta-xylene, it serves as a critical raw material in the manufacture of high-performance polyesters, resins, and coatings.

Request a Free Sample – https://www.procurementresource.com/reports/isophthalic-acid-manufacturing-plant-project-report/request-sample

Primary Applications

- Polyester Resins: Isophthalic acid is a key component in unsaturated polyester resins, which are used in automotive parts, construction materials, and consumer goods.

- PET Packaging: It improves the performance of polyethylene terephthalate (PET) by enhancing clarity, strength, and heat resistance, making it ideal for beverage bottles and food containers.

- Coatings and Paints: Its use in alkyd resins leads to better durability, gloss, and adhesion, ensuring long-lasting coatings for various surfaces.

By understanding these applications, manufacturers can align their production strategies with market needs, ensuring consistent demand for their output.

Key Components of an Isophthalic Acid Manufacturing Plant Project Report

A detailed project report outlines the technical, economic, and operational aspects of setting up a manufacturing plant. It typically includes the following sections:

Read Full Report With Table Of Contents – https://www.procurementresource.com/reports/isophthalic-acid-manufacturing-plant-project-report/toc

Raw Materials and Procurement Strategies

The primary raw material for producing isophthalic acid is meta-xylene, which is oxidized in the presence of a catalyst to yield the final product. The report should detail sourcing strategies, supplier selection, and inventory management. Leveraging modern procurement resources can ensure a steady supply of quality raw materials, minimize costs, and reduce production downtime.

Production Process and Technology

A comprehensive project report explains the production process, including:

- Oxidation Reaction: Meta-xylene is oxidized using air in the presence of a catalyst, often cobalt or manganese, to produce isophthalic acid.

- Purification Steps: The crude product undergoes purification processes such as crystallization and drying to achieve the desired purity levels.

- Packaging and Storage: The final product is packed and stored under controlled conditions to maintain quality.

By detailing each step, the report helps in identifying the most efficient technologies and equipment, ensuring smooth operations and high-quality output.

Plant Layout and Infrastructure

An efficient plant layout minimizes material handling, reduces energy consumption, and improves workflow. The project report should provide a detailed layout that includes reactor placement, utility areas, storage facilities, and quality control labs. Proper infrastructure planning ensures that the plant meets safety standards and is prepared for future expansions.

Market Analysis and Demand Projections

Understanding market dynamics is critical for the success of any manufacturing venture. The project report should include:

- Current Market Trends: Growing demand for high-performance polymers and coatings has boosted the need for isophthalic acid. Analyzing these trends helps in forecasting future demand.

- Regional Insights: Identifying key consumption regions, such as North America, Europe, and Asia-Pacific, enables targeted marketing and distribution strategies.

- Competitor Analysis: Evaluating the competitive landscape helps in positioning the product effectively and identifying growth opportunities.

Financial Feasibility and Cost Analysis

A significant portion of the project report is dedicated to financial feasibility, covering:

- Capital Expenditure (CAPEX): Costs for land acquisition, plant construction, equipment, and initial setup.

- Operational Expenditure (OPEX): Costs for raw materials, labor, utilities, maintenance, and transportation.

- Revenue Forecasts: Projected income based on production capacity, market demand, and pricing strategies.

By providing a detailed financial analysis, the report helps investors and stakeholders understand the project’s profitability, payback period, and return on investment (ROI).

Environmental and Regulatory Considerations

Setting up an isophthalic acid manufacturing plant involves compliance with environmental and safety regulations. The project report should outline:

- Emission Controls: Measures to reduce air pollutants and maintain compliance with local regulations.

- Waste Management: Strategies for handling by-products and minimizing waste generation.

- Energy Efficiency: Implementing energy-saving technologies to lower operational costs and reduce the carbon footprint.

By addressing these considerations, manufacturers can ensure a sustainable and environmentally responsible operation.

Importance of Procurement Resources

Effective procurement plays a crucial role in maintaining production schedules, controlling costs, and ensuring consistent quality. Incorporating advanced procurement resources into the project report enables:

- Supplier Optimization: Identifying reliable suppliers who can provide high-quality raw materials at competitive prices.

- Cost Savings: Leveraging bulk purchasing and long-term contracts to secure better rates and reduce expenses.

- Risk Mitigation: Developing contingency plans to address supply chain disruptions and price volatility.

Utilizing procurement resources ultimately enhances the efficiency and profitability of the manufacturing plant.

A comprehensive Isophthalic Acid Manufacturing Plant Project Report provides a detailed roadmap for setting up and operating a successful facility. By including insights into raw materials, production processes, market trends, financial feasibility, and regulatory compliance, the report ensures that manufacturers are well-prepared to meet market demands while maintaining cost efficiency and environmental responsibility.

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA